About Us

-

2000

YearFounded

-

4000

㎡Factory scale

-

100

+Number of employees

-

20

YearProfessional Experience

-

20

TtemCertification

HuiZhou HengLiangXing Industrial Co.,Ltd

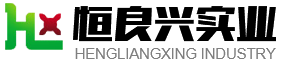

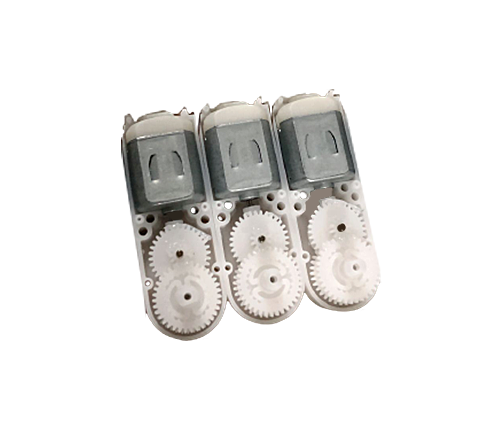

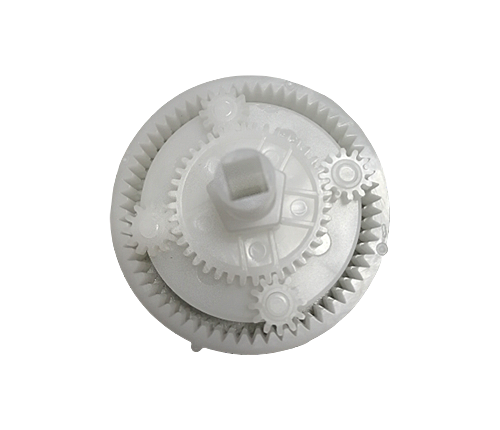

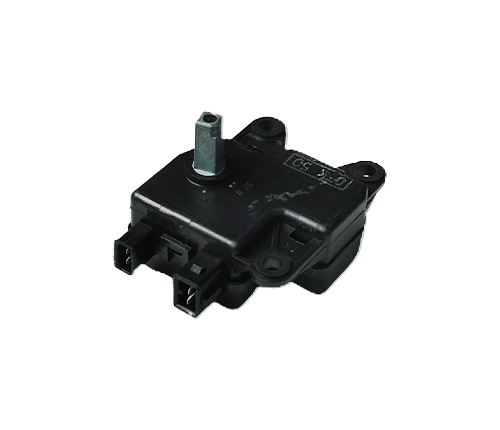

Huizhou Hengliangxing Industrial Co., Ltd. was established in 2000. It is a professional manufacturer of precision gears, worm gears, worm drive mechanism systems and other high-precision plastic parts and plastic tooth box products. The company has a team of highly efficient and skilled managers and technicians with 20 years of development and manufacturing experience. In May 2021, the newly built plant covers an area of more than 4,000 square meters, and advanced mold room equipment, injection molding machines, and testing equipment have been added to meet the ever-expanding production needs. With the evolution of the times, various products have become more and more value-added and meet the needs of high-precision, precision and special teeth and accessories.

Application

News

23

2021-08

When mold manufacturing collides with Industry 4.0

23

2021-08

[Basic terms of gears] Mating gears Mating gears

23

2021-08

How to prevent the entry of 6 types of pollutants in gear pumps

Huizhou Hengliangxing Industry Co., Ltd.

Telephone:0752-2854971/13516685011

E-mail:sales@hengliangxing.com

Address: 43 Xinglong West Second Street, Xiaojinkou, Huizhou City, Guangdong

Website:www.hengliangxing.com

©Copyright 2024 All rights reserved of Huizhou Hengliangxing Industrial Co., Ltd.